September 14, 2020

What happens when a hospital’s chiller, which plays a critical role in providing optimal conditions for patients and medical professionals, breaks down in the middle of a West Texas summer?

Covenant Children’s Hospital is one of the only hospitals in the region licensed by the Centers for Medicare and Medicaid Services (CMS) as a Children's Hospital. Families across the region trust and rely on Covenant Children’s for vital medical procedures and care for the most vulnerable and tiniest of patients.

Many large commercial businesses, including hospitals, use a circulating water system for their Heating, Ventilation and Air Conditioning (HVAC) systems. Part of the system includes a chiller – a device that cools the circulating water, and then pushes it out as cool air throughout the building.

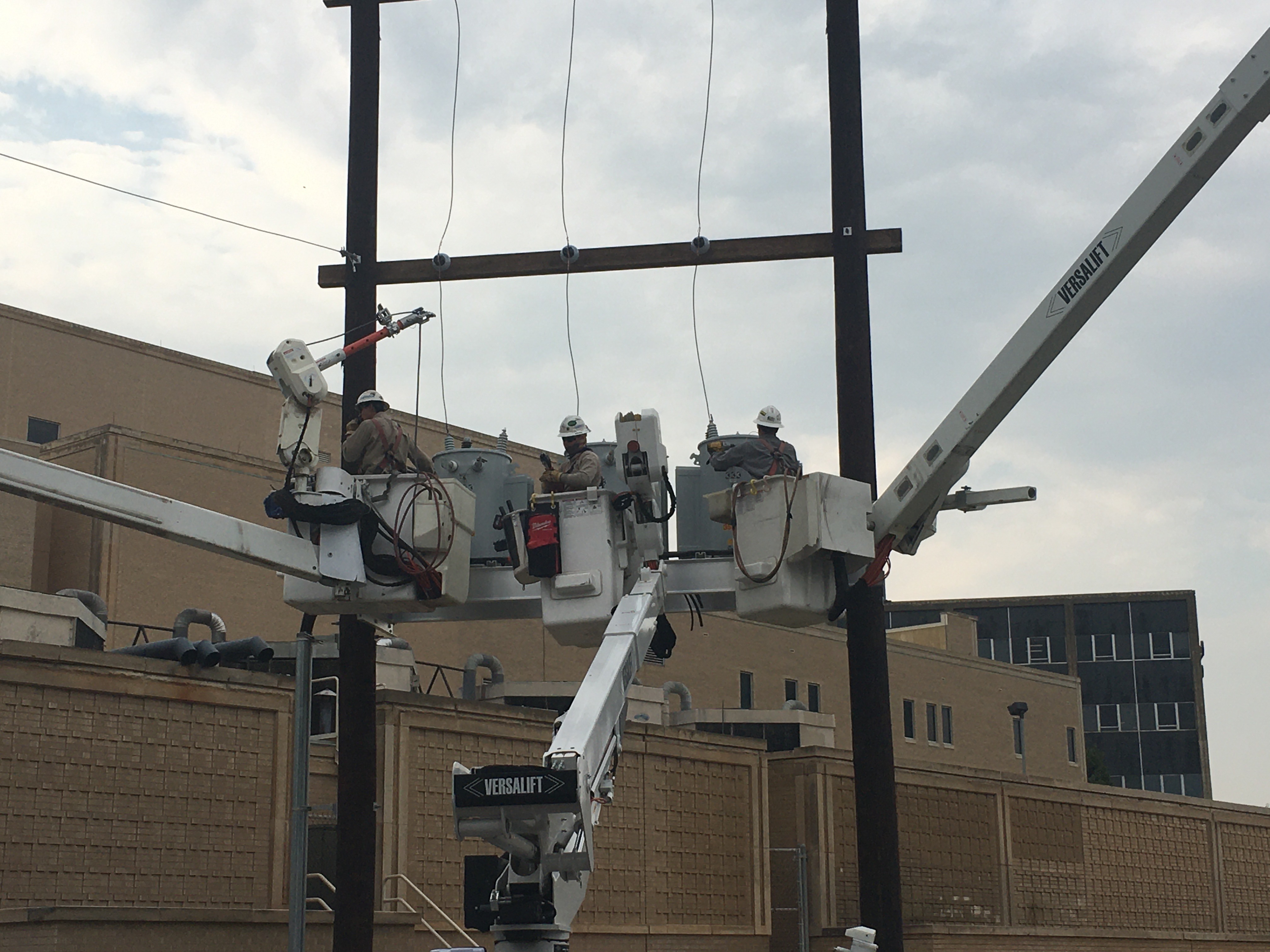

When Covenant Children’s Hospital realized their HVAC system wasn’t working properly, Gary Davis, director of plant operations at Covenant Children’s, immediately reached out to LP&L for help. LP&L jumped into action to develop and implement a plan to install a power feed for the 1,000-amp chiller.

“We knew we had to get the power feed to the chiller installed as quickly and safely as possible. Over 40 infants in the hospital’s neonatal intensive care unit and many others depended on it,” said Brady Anderson, LP&L senior power line foreman.

Over the period of an entire week and all-day Saturday, the 11-person LP&L team constructed a new platform and other requirements for the chiller, working through 100-degree-plus temperatures.

“We are so thankful to LP&L for their careful attention to detail and exemplary attitude in constructing the power feed for the chiller which serves our vulnerable and high-risk patients,” said Davis.